Decoupling loudspeakers the right way

Decoupling loudspeakers in control rooms is a key step that significantly improves their response within the listening environment. While proper room acoustics are the foundation to critical listening, ensuring your loudspeakers are effectively decoupled from their stands or walls can provide major improvements in the system's overall performance.

What are the benefits of decoupling speakers

When a loudspeaker is placed directly on a stand or desk without decoupling, the cabinet's mechanical energy is transferred into the supporting structure, causing it to vibrate sympathetically. This effectively turns your desk, stands or floor into a secondary, uncontrolled radiator that blurs the sound. By decoupling the speaker you break this mechanical bridge. This ensures that the energy generated by the drivers remains focused on moving the air, rather than shaking the room's structure, resulting in a tighter, more accurate low-end response and a significantly clearer stereo image.

Beyond just bass management, decoupling can improve the speaker's transient response. When a cabinet is free to vibrate against a rigid surface, micro-movements can smear the transient of a sound, particularly in the lower mid range. Proper isolation stabilizes the speaker, allowing the drivers to stop and start more precisely. The result is a more defined stereo image, better depth of field, and a monitoring environment where you can trust that what you are hearing is the source material, not the resonance of your furniture or room.

Image 2. The original mastering room at Arda Recorders during loudspeaker installation in 2020, showing the ATC SCM110ASL Pro speakers fully decoupled inside an unsealed enclosure to allow for measurements and pad adjustment.

Is bottom-only decoupling enough?

This brings up a common concern regarding physics: if a speaker is only 'floating' won't the forward motion of the woofer push the cabinet backward? According to Newton’s third law, that energy has to go somewhere, and without a rigid connection, the cabinet is subject to micro-movements that can theoretically smear transients. However, in almost all listening scenarios, the audible distortion caused by a resonant floor/desk or stand 'singing' along with your bass is far more destructive than the effects of cabinet recoil. Generally speaking, breaking that mechanical bridge is the superior trade-off.

To get the best of both worlds - decoupling and stability - you can introduce mass to the equation. A highly effective solution is to place a heavy slab of stone or granite, even a solid concrete block, directly under the speaker, with the isolation pads or springs placed underneath that heavy footing. This increases the total inertia of the system. The heavy mass acts as an anchor that resists the cabinet's recoil, allowing the drivers to fire from a stable position, while the isolation material underneath continues to do its job of preventing energy from leaking into the building structure.

For in-wall configurations, the loudspeaker should ideally be decoupled omnidirectionally: floating from the top, bottom, and sides. The most effective method is to house the speaker within a heavy, dampened box, 'press-fitting' it against isolation pads or springs under compression. This entire module is then installed into the wall. While this increases the complexity of the load calculations - as you must now account not only for the speaker's weight distribution but also for the additional downward force exerted by the compressed top pads/springs - it maximizes isolation and allows the system (box + loudspeaker) to be removed as a single unit for maintenance.

What works for decoupling (and what doesn't)

A common DIY misconception is that anything soft will isolate a speaker. This leads people to use items like tennis balls cut in half, rubber pads, standard packing foam, acoustic foam or even slabs of high-density rock wool. These are generally ineffective as they lack true spring-like properties even though some of these can be considered dampers. As a good rule of thumb for ready-made solutions: if a product is defined primarily by a shore hardness rating, it is likely a damper rather than a true spring-like isolator.

True decoupling requires a material that acts as a tuned mechanical low-pass filter. For heavy loudspeakers, metal springs are often the most efficient solution because they offer a very low natural frequency, though they can introduce resonance if not properly damped. A more versatile modern alternative is the use of micro-cellular polyurethane elastomers, such as Sylomer or Regufoam. These materials are "spring-like" foams engineered with specific densities to handle precise weight ranges. Unlike generic rubber, they behave like a spring combined with a shock absorber, effectively isolating vibrations without the ringing associated with undamped metal coils.

The most critical factor in choosing these materials is static deflection: essentially, how much the material compresses under the speaker's weight. Decoupling is physics and for a pad to work it must be loaded correctly. If you place a light speaker on a stiff pad, the pad won't compress enough to act as a spring, and the vibrations will pass right through. The opposite is also true, if the speaker is too heavy to the pad, the material will bottom out and become a solid bridge.

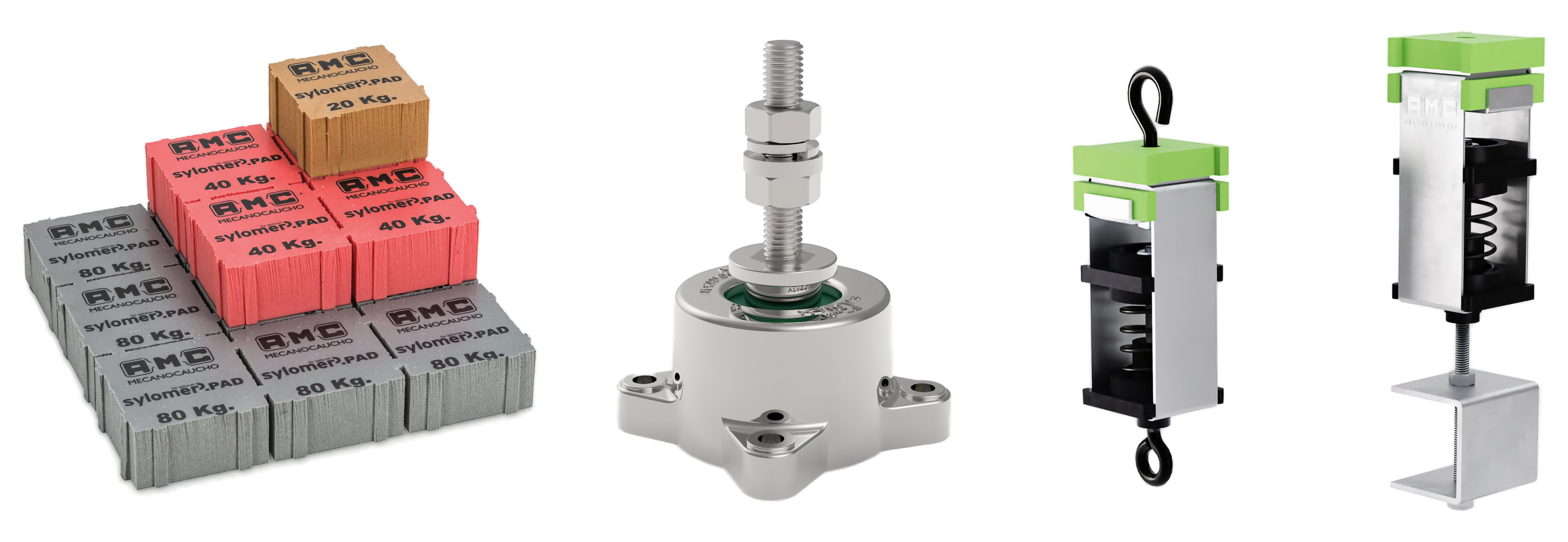

Image 1. Three examples of different Sylomer pads and spring mounts from AMC Mecanocaucho.

Calculating the load: it’s all about the maths

Choosing the right decouplers is a matter of simple but critical arithmetic. You cannot guess what to use and you must calculate. The first step is to consult the manufacturer's specification sheet for the exact weight of your loudspeaker, considering that single number is rarely enough. Most loudspeakers, particularly passive models with heavy magnets on the drivers, are front-heavy. This shifts the center of gravity forward, meaning the front pads or springs will bear significantly more load than the rear ones. If you use four identical pads in a square, the front two might be overloaded (bottoming out) while the rear two are underloaded (too stiff to isolate), compromising the entire system.

To solve this, you need to calculate the load per mounting point. If you are using a material like Sylomer, the manufacturer provides data sheets specifying the optimal static load range for each color-coded density. For example, a yellow Sylomer pad measuring 100x100x25mm might work best between 9-10kg, while an orange one with the same dimensions requires 14-16kg to function as intended (note, different manufacturers may have different color codes). You may need to use different densities for the front and rear, or adjust the spacing of the pads to balance the weight distribution. Load capacity is usually stated as N/mm2 per color, so getting the right pad requires both getting the right dimension and the right color.

The final and most important step is verification. Once the speakers are placed on the mounts, you must measure the deflection: the actual amount the spring or pad has compressed. For springs, this is usually a straightforward measurement of height and for elastomers like Sylomer you are looking for a specific percentage of compression (often around 10-20% depending on the type), to ensure the material is in its linear elastic region. As stated previously, if a pad isn't deflecting enough, it's acting as a solid block; if it's squashed flat, it's bridging. Adjusting the number of pads or their position until you achieve uniform, specified deflection across all points is the only way to guarantee the system is truly decoupled.

Image 3. Measuring deflection on individual Sylomer pads with the one and only @AvE ruler to ensure correct loading.

Ready-made solutions: when you just want to plug and play

If the math seems daunting or you simply prefer a verified, finished product, there are excellent off-the-shelf options that utilize these exact engineering principles. Unlike generic foam wedges or isolation rubber pucks, companies like Mesanovic and Space Lab Systems engineer their stands and platforms using calibrated Sylomer or spring-based isolation. These products take the guesswork out of the equation, providing a pre-tuned mass-spring system. By selecting the model that matches your speaker's weight range, you get a guaranteed low natural frequency and correct deflection right out of the box, without needing to cut foam or measure compression yourself.